How to plan hydraulics in a marine aquarium? To understand this topic, you need to know the basic structure of a marine aquarium and consider several aspects.

Below in the diagram, I have highlighted 14 key elements that we need to understand before planning our hydraulic model for a marine aquarium.

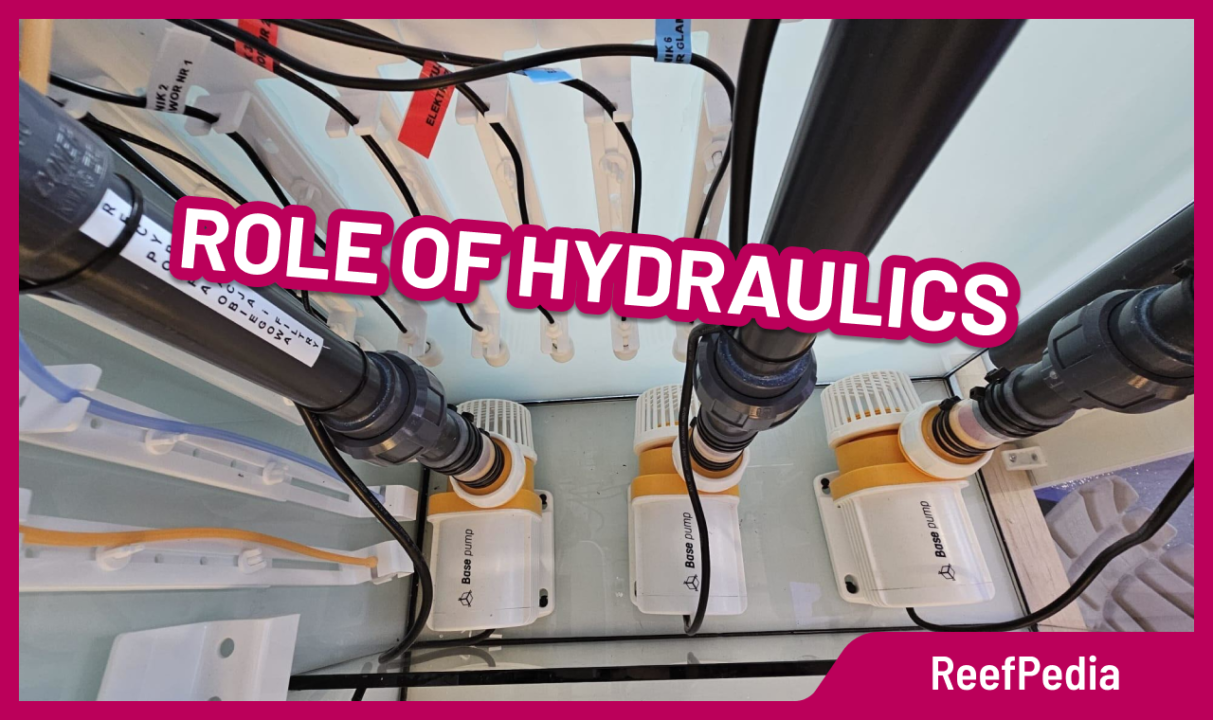

- Base pump

The water between the top and bottom aquarium is constantly moving. Water from the top aquarium spills over through a pipe, falls into the sump, and then is pumped back into the aquarium using a base pump (1). How to choose the right pump power, we described in a separate article available [here]. - Pipe from the base pump to the aquarium

It’s important to consider a few key aspects. The diameter of the base pump’s pipe should be chosen properly to not restrict the pump’s flow. It is recommended to choose PVC fittings that do not slow down the flow; instead of 90-degree elbows, it is better to use two 45-degree elbows or a 90-degree bend. - Water level when the base pump is off

When the pump stops working, the water level returns to the starting point. When the pump is operating, it raises the water level by several centimeters. - Air vent for the base pump

An air vent is essential so that if the base pump stops working, it will not suck water all the way to the end of the pipe entering the aquarium but will air lock and stop according to the standing water line (3). Such a hole should be made between the resting water level (3) and the water level when the aquarium is operating (5). The diameter of the hole can be 3-4 mm. Remember that when performing service work on the aquarium, this hole needs to be regularly cleaned. If the hole does not air lock the water in the pump’s pipe, when it stops working, the water will drop to the level of the end of the immersed inlet pipe from the base pump that is in the aquarium. This may cause more water to go down to the sump than planned, which can cause the sump to overflow and spill water on the floor. - Water level in the aquarium during the operation of the base pump

Be aware that the water level in the aquarium is slightly higher when the base pump pushes water from the sump into the aquarium. - Water level without air venting of the base pump

The water level in the aquarium when the pump would stop and there is no air venting of the pump pipe. - Water level in the sump when the pump is operatingWhen the base pump stops, the water level in the sump rises because the water from the aquarium flows back into the sump.

- Downflow pipe

This is a crucial pipe for the logic of water circulation. The diameter cannot be too small to ensure an adequate amount of water supplied by the base pump. Here are examples of pipe diameters I’ve used in my aquarium projects:

– up to 100L – 20 mm

– 101-300 L – 25 mm

– 301-600 L – 32 mm

– 601-1000 L – 40 mm - The ball valve on the drain pipe

It is recommended to install a ball valve on the drain pipe, and if the budget allows, a gate valve. This allows for gently damping the water flow, which raises the water level in the pipe and ensures quietness in the aquarium. After starting the circulation, the valve can be slightly tightened to keep the water level in the pipe about 0.5 cm below the entry to the inspection pipe. - Pass-throughs through the glass

The place where the pipes go from the pipe to the sump requires proper preparation of holes in the bottom of the aquarium. The holes must be large enough to fit the pass-through, but also properly located to provide space for the flanges. In practice, they should be properly spaced from the walls and from each other. A common mistake by beginner glassmakers is drilling holes too close to each other or to walls, which makes it difficult to install pass-throughs. Here are the diameters of pass-throughs and corresponding hole sizes for typical Aqua Medic pass-throughs:

– TV25 – 35 mm (pass-through for 25 mm pipes, 35 mm hole in the glass)

– TV32 – 45 mm (pass-through for 32 mm pipes, 45 mm hole in the glass)

– TV40 – 60 mm (pass-through for 40 mm pipes, 60 mm hole in the glass)To properly place the holes in the pipe, it’s worth drawing a model on paper or cardboard first. More information on this topic can be found in the article here: [link to the article].

- Drain strainer

We insert a strainer into the water drain pass-through, which protects against clogging of the drain. The strainer protects the flow from snails and other impurities. - Inspection pipe

This pipe is used to secure the water flow. If the main drain is blocked, water can flow through the inspection pipe. This pipe should be glued into the pass-through and should be almost as tall as the pipe but about 1.5-2 cm lower. - Water pipe

Typically, the height of the water pipe in the aquarium is about 5-6 cm lower than the height of the aquarium. - Water level in the pipe

As mentioned, the water level in the pipe should be slightly lower than the inspection pipe to avoid unwanted noise when water spontaneously flows into the inspection pipe. The water level in the pipe is adjusted using a ball valve.

Understanding these elements of water circulation in an aquarium and proper planning of hydraulics is key to success. Additional information on hydraulic work and practical tips can be found in a dedicated article available here: [link to the article].

About the author

Marek Protasewicz

Reefkeeping has been my passion for over 10 years now. I love learning. The hobby has taught me many valuable lessons, patience being the best example. Combining work and passion is my path. I run Crazy Coral, a marine aquarium shop, for a number of years. Building this business from the scratch I learnt from my own mistakes at a heavy cost.

Later I managed a project aimed at development of methods for quick growth of Corals in non-natural conditions. The project was carried out by Get Sales, Poland. Presently, I am responsible for distribution strategy at Reef Factory, of which I am a co-founder. The company produces smart devices for marine aquaristics. The last projects I have been involved in are Social Reef and ReefPedia.